Decal Doming with P.U. or Epoxies

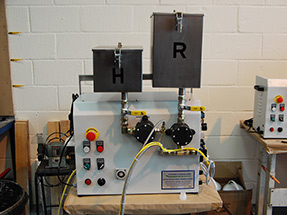

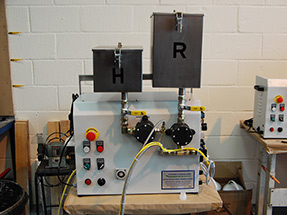

Iota 'C'

Small, bench mounted machine using a pair of ‘Captive’ type single acting piston metering pumps and designed to minimise outgassing during the reload cycle, thus eliminating the bubbles often found with competitors piston pump machines. These are sized to give the precise mix ratio and feed directly to a disposable static mixer. Primarily used for manually dispensing single shots and on typical P.U.s’ and Epoxies, precise, discrete, volumetrically metered and mixed shots down to less than 0.2gms can be achieved with cycle rates of up to 45 –50 shots per minute.

MiniRim ‘D'

Small bench mounted machine, using low pressure gear pumps for metering. The pumps are linked together by a timing belt, with toothed pulleys used to set the mixing ratio and driven by variable speed invertor controlled motor. The drive is fitted with a selector switch to give either, a pre-set shot weight, using an adjustable timer or an external control of shot size. PTFE lined hoses are used to feed the mixing head, which can either be a disposable static, rotary static or dynamic type, fitted with the option of Solvent/Air flushing.

The MiniRim can manually or robotically controlled, dispense an accurately metered single 1gram shot, or apply say 50gms. shot or bead at controlled rate and with the solvent flush option be fitted with a multi-branch outlet manifold.

MasterCaster

Floor mounted, high output machine using low pressure gear pumps for metering. The pumps are independently driven via electro-magnetic clutches by variable speed invertor controlled motors to providing high frequency cycle rates and electronically interlocked to provide a programmable mix ratio. A selector switch offers either timed shot size dispensing for precise shot weights or external control for bead laying at controlled rate. Mixing can be either disposable static, rotary static or dynamic type and fitted with Solvent/Air flushing.

The MasterCaster is a high output unit and if required can be supplied as a complete station complete with multi-outlet manifold and nozzle holder assembly, together with vacuum table mounted on guide bars and curing table. Other typical options include de-gassing reservoirs, direct feed from supply drums.