Piston Pump Range

Comprising three designs of single acting volumetric metering pump, driven with pneumatic cylinders or a +recirculatory ball screw and programmable motor. To provide proven capability of accurately metered discrete, controlled rate shots or beads of 0.006ml to1.0L.

IOTA RANGE:

Specifically designed to dispense small amounts on a pre-set ratio, either as discrete volumetrically metered discrete shot or laying beads at controlled rates.

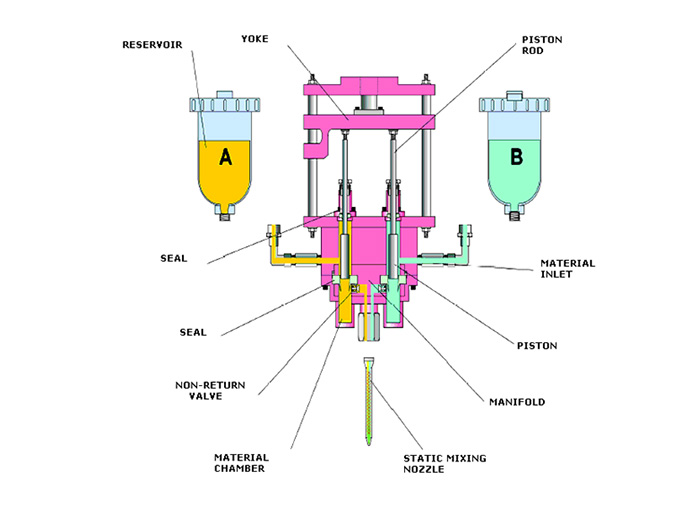

Iota ‘R’

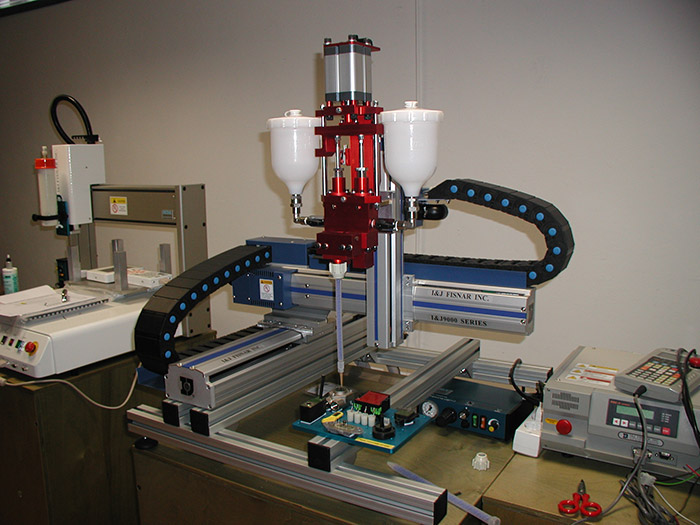

This was initially designed for a robot to meter and mix at the point of application thus eliminating the problem of hose hysteresis and giving exceptional dispensing rate control. We then fitted it to a bench stand.

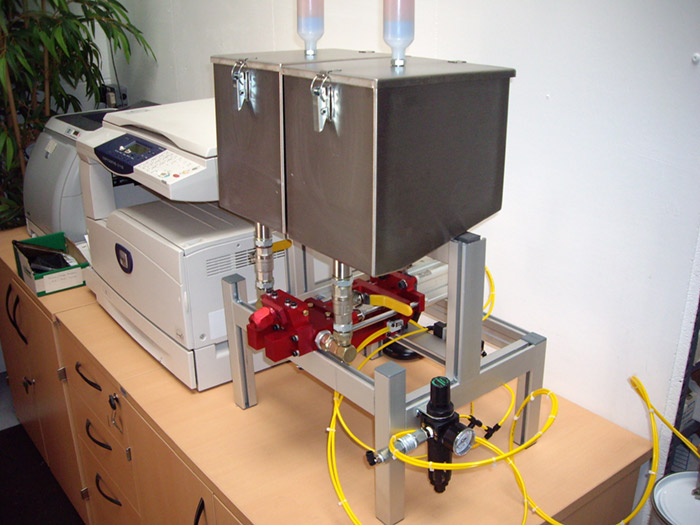

Iota ‘B’

Machine uses the Iota ‘R’ module, but is mounted on to an extruded frame to enable support larger reservoirs, control cabinet or to fit hoses and a hand held mixing gun.

Iota ‘C’

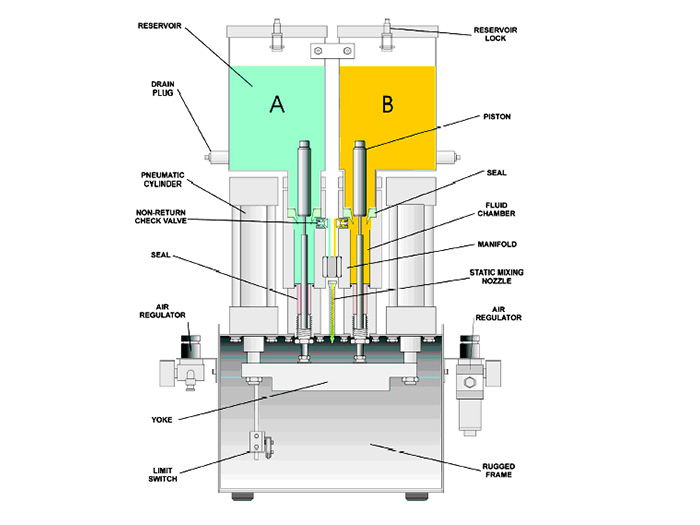

Machine uses our ‘Captive’ piston pump design, providing controlled flow on the dispensing stroke and prevents out-gassing during the reload stroke. Moreover, the design can be built as multiple modules with a common drive.

2 MIX GM RANGE:

The GMC is the larger output range, design to be a general purpose machine with varying output capabilities, using two pump designs and mounted with the drive cylinders on to a stiff folded box shaped frame or in a channel section carrier.

The metering pumps can be sized to give the precise volumetric ratios over a 1:1 to 50:1 range and depending on the type and size outputs ranging from 3cc to 1L per cycle.

For mixing, a disposable static, rotary static or high shear dynamic is used in the form of hand held guns or remote mounted heads.

The ‘GM’ is a mid range output machine, it can be bench with a fixed mixer floor mounted on casters with a mixing gun on hoses or mounted into an extruded section frame to support larger reservoirs. Moreover, because the reservoirs are mounted directly on to the pump inlet they can gravity load high viscosity/thixotropy materials.

GMC large output machine designed to be modular with the metering pumps and drive cylinders mounted on to a channel section carrier, allowing it to be mounted vertically or horizontally and enabling it to be fitted with gravity feed reservoirs, connecting to a bulk supply or a combination of both.

2 MIX DCF, DCV & DCS Range

2MIX DCF/DCV/DCS machine range use captive type pumps for processing high viscosity or thixotropic adhesives and sealants direct from the suppliers open-topped supply drum. The hardener or curative being fed from either a machine mounted reservoir or remotely using a pressure vessel or a secondary transfer/extrusion pump.

DCF machine is pneumatically powered with the metering pumps diameters sized to fix the mix ratio and driven by a common cylinder. The metering pump/drive module mounted on to a twin post lift/lower ram assembly.

The base material is metered directly from the supply drum using a follower plate drum fitted with a metering pump in the centre, the hardener/curative is fed from machine mounted reservoir, remote pressure vessel or secondary transfer/extrusion pump.

DCV is similar to the DCF but uses a linkage assembly to provide ratio adjustment.

DCS machine the proven ‘captive’ type metering pumps fitted to the centre of the follower plate and mounted to a lift/lower ram assembly. However, the metering pumps are driven by a re-circulatory ball-screw and geared servo motors, interlocked together which enables two viscous materials to be metered from separate supply drums.